Building a nuc box is really no different from building the boxes for a standard Langstroth hive. It’s really just a smaller version. It’s also not a complicated project and is fairly easy for the DIY guy or gal. I chose to make my own nuc boxes for the following reasons: First, I didn’t want to buy a cardboard nuc box from my bee supplier and end up tossing it into the recycle box. Second, I’ve built everything else for my hives, so why stop at this. Third, I’m planning on either using these boxes for future swarm traps or creating additional colonies by “splitting” my original colonies in the future.

So…..lets get started. But first, lets talk about safety. Make sure that you read and understand how to SAFELY operate your power equipment. In some of the pictures below, the safety guard has been removed so that you can get a better understanding of the photo. NEVER operate your equipment without a guard in place!

Nuc Box

In order to begin, you are going to need some 1×12 lumber or some glued up 1×6. I choose the second option because it was what I had available in the shop.

Begin by cutting the pieces of the box to the required length and width.

The front & back are 3/4″ x 7- 1/2″ x 11″.

The sides are 3/4″ x 19- 7/8″ x 11″ .

The bottom is 3/4″ x 7- 1/2″ x 18- 3/8″.

Using a 3/8″ countersink bit, drill the holes for the screw locations on each piece to a depth of 3/8″.

Using a 7/8″ forstner bit, drill the hole for the entrance. The center point for this hole should be 1-1/4″ from the bottom of the front.

Now, cut the rabbet joint on the inside of the front & back. This joint will support the frames.. This joint can be made in two passes on the table saw. First, set the rip fence to 3/8″ and the blade height to 3/4″. Use a feather board clamped to the table saw top in order to help stabilize the stock as it passes over the blade.

Next, lower the blade to 3/8″ and adjust the rip fence so that there is 3/4″ from the left side of the blade to the fence.

Now assemble the box using 1- 1/2″ galvanized screws and glue.

Fill the screw holes with wooden plugs, trim to flush and sand the box.

If you would like to make handles for your nuc box, CLICK HERE to see how I made them for my standard hives.

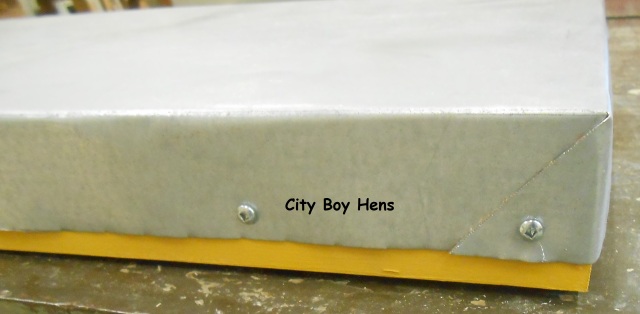

Top

Material List:

Plywood – 3/4″ x 9-1/2″x 20-1/2″.

Front & back strips – 3/4″ x 2″ x 9-1/2″.

Side strips – 3/4″ x 2″ x 22″.

Metal covering – 14-1/2″ x 25-1/2″.

Begin by cutting these pieces to the required width & length and countersinking screw locations in the front, back & side strips.

Just like the nuc box, glue, screw, plug and sand the assemble top.

Next, paint the top before securing the metal “roof”.

Once the paint is dry, evenly position the and trace the circumference of the roof on the metal sheet. These pencil lines will become the 90 degree edges that must be bent for the top. Using metal shears, cut a 45 degree angle from each edge of the metal sheet to the outline edge of the top.

Using a 90 degree edge (like the end of your table saw) begin bending the metal along the two sides. Take your time and only exert a bit of pressure as you move down the line. Continue repeating this process until you have a nice crisp edge.

Now screw those edges to the sides of the top with #6 x 1/2″ pan head metal screws.

Next, fold the 45 degree edge (from the side) on to the front/back and begin bending the edge for the front/back.  Fold the 45 degree edge (from the front/back) to the side and secure these areas with screws.

Fold the 45 degree edge (from the front/back) to the side and secure these areas with screws.

Inner Cover

Material List:

Plywood – 1/4″ x 7-1/4″ x 18-1/8″

Front & Back Strips – 3/4″ x 1 – 1/4″ x 9″

Side Strips- 3/4″ x 1-1/4″ x 19-7/8″

Using a 7/8″Forstner bit, drill two holes in the center of the plywood so that the distance is 3 – 3/4″ in length from the outside of each circle. Cut out the rest of the shape using a scroll saw, jig saw or coping saw.

The front & back strips of the inner cover are connected together by creating a lap joint. It’s a fairly easy joint to make and consists of removing half of the thickness of stock on the opposing face of each piece. In order to make this joint, set the table saw blade to 3/8″ and remove 1-1/4″ from the opposite ends of each strip. This will be done in several passes if a dado blade is not used. Never cross-cut stock with a miter gauge when it is butted up to the rip fence. This could potentially bind the stock and cause kick-back. Instead, use an auxiliary fence for this procedure.

Using the table saw, cut the 1/4″ slot in the front, back & side strips which will receive the plywood. Set the table saw blade to 3/8″ for height and the fence to 3/8″ from the left side of the blade. Using a feather board for additional support, rip this slot in the above mentioned pieces. Adjust the rip fence (depending on the thickness of your blade) to make a second pass in order to complete the 1/4″ slot. Don’t forget to alternate your strips for this step!

Next, cut the entrance in the inner cover. I made mine 3/8″ x 3/4″.

Finally, glue the pieces together and sand after the glue has completely cured.

If you would like to learn how to build your own 10 frame Langstroth hive CLICK HERE.

Best of success.

Regards,

CB