It’s hard to believe, but these tiny bugs are one of the leading causes to the honey bee’s demise. They are about the size of a pin head, are named Varroa Destructor and…….I’ve got ’em in my hives. These little buggers attach themselves to a honey bee, weaken the bee as they suck their blood and pass on various viruses as a parting gift to the bee. If not controlled, the mites will eventually take down the entire colony.

The varroa mite was nowhere to be found in North America before the 1980s. Though it was firmly entrenched in Europe and Asia, bee keepers in North America had no issues with this parasite before this time. According to the old-timers, “pre-varroa” was a great time to be a beekeeper on our continent. Nobody knew what Colony Collapse Disorder (CCD) was and the honey bee and the beekeeper generally flew under everybody’s radar.

Fast forward 30 years later and we’re in a totally different boat. Harsh chemicals have failed to be the answer to the demise of varroa as these parasites continue to wreak havoc for most beekeepers. So……what’s a beekeeper suppose to do?

Option #1: Do nothing and hope that the bees figure out how to over-run these parasites. This hasn’t proven to be too effective for most backyard beekeepers, though certain people in the industry claim that they now have varroa resistant bees.

Option #2: Treat the hives with harsh miticide chemicals to kill the varroa. This also hasn’t proven to be that effective since the mite has learned to become resistant to these insecticides. Not to mention that the residue from a lot of these chemicals is now being found to contaminate the comb that bees use to store honey and raise new bees.

Option #3: Develop an Integrated Pest Management (IPM) system which involves adopting “safer” strategies in order to keep varroa numbers at a level that will not allow them to destroy a colony over time. Examples of this include:

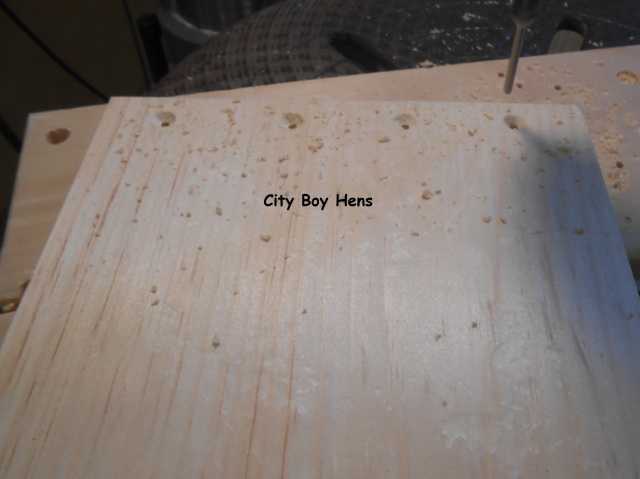

A) Using screened bottom boards which do not allow a fallen mite to re-enter a colony.

B) Culling drone brood (male bees). This “intelligent” parasite has figured out that it can breed and suck on the bee’s bodily fluid for an extra 3 days in capped male brood rather than the female brood. As a result, the female mite favors mating and raising new mites in the comb where male bees develop. By opening this comb and removing the drone brood, the beekeeper also removes a lot of mites who, in turn, would mate and increase their numbers within the hive.

C) Using natural treatments like formic and oxalic acids at designated times in the year. Formic acid is naturally found in many foods including apples, strawberries, raspberries and……….. honey. Oxalic acid can be found in spinach, Swiss chard, beet tops and parsley. In high concentrations, they are poisonous to humans. This is why we do not eat rhubarb leaves. Fortunately, these acids are also lethal to varroa mites and, when used in the right application, can really knock down the mite numbers in a hive. Best of all, these acids have been certified as “safe” chemicals that allow the organic beekeeper to continue to consume and sell a safe edible honey.

As Michael Corleone said “Keep your friends close and your enemies closer”. Varroa mites are not leaving anytime soon. In fact, they are probably here to stay. Hence, I’ll do what I can to help my bees maintain the upper hand on this incredibly destructive pest. It’s the least I can do to help this incredible insect!

On Sunday morning, I met up with Dan and brought my hive to its new home. It will sit in his barn for a few weeks until we can purchase a few more queens and re-start the 2 other hives.

On Sunday morning, I met up with Dan and brought my hive to its new home. It will sit in his barn for a few weeks until we can purchase a few more queens and re-start the 2 other hives.